Since 1968, Jean Claude Comby, founder of ACFRI, has been developing a range of rapid cooling and deep-freezing cells using vertical tube evaporator technology.

This technology offers many advantages:

Chilling is achieved at a very low temperature without

risk of products freezing too quickly.

Ventilation and temperature are uniform over the height of the trolley, so products at the top of the trolley reach the end of the cycle at the same time as those at the bottom.

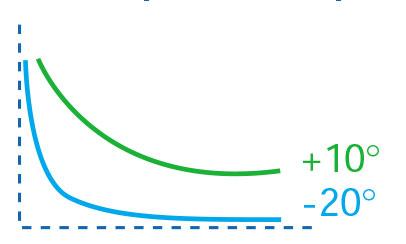

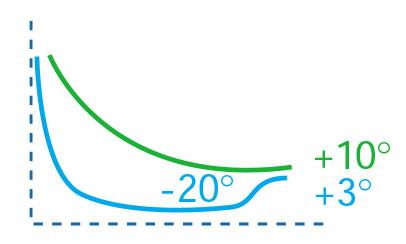

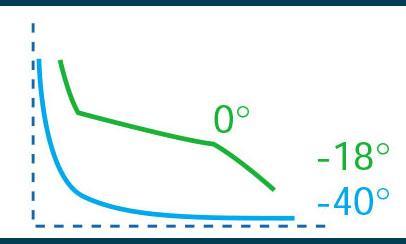

The principle of blast chilling and mechanical freezing is based on the temperature difference between the product and the blown air. The greater the temperature difference, the shorter the cycle. In both rapid chilling and deep-freezing, a cell must therefore be capable of producing a negative blast temperature.

To reach a core temperature of +10°C, some products need to be blown down to -20°C.

Some products that are more fragile and easier to cool may be satisfied with controlled blowing throughout the cycle (see ACFRI temp'progressif solution).

To quickly reach a core temperature of -18°C, all products require intense blowing between -30°C and -40°C.

The air speed allows the exchange of heat that is essential for the rapid cooling of a product.

The more a product is ventilated, the faster it cools. If rapid cooling is achieved by blowing cold air at sub-zero temperatures, it is essential to ensure that all products are blown in at the same rate, otherwise the first products to be cooled may freeze prematurely.

Some of the more demanding products require specific, highly ventilated cooling.

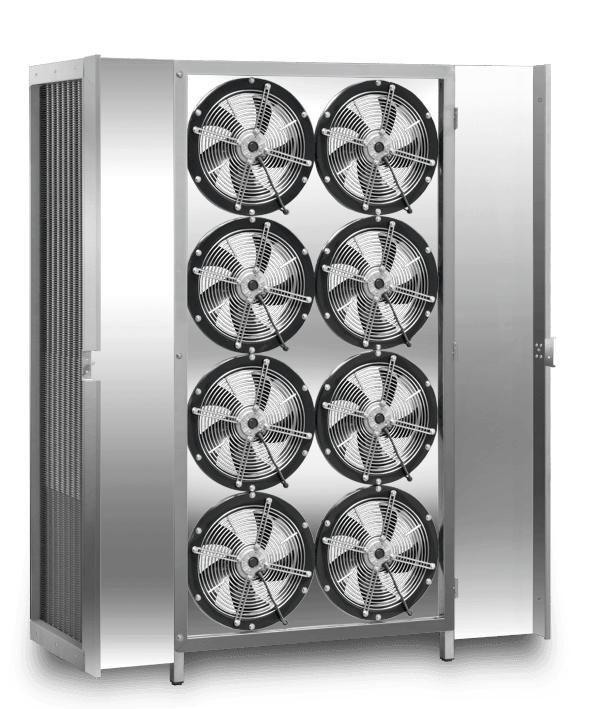

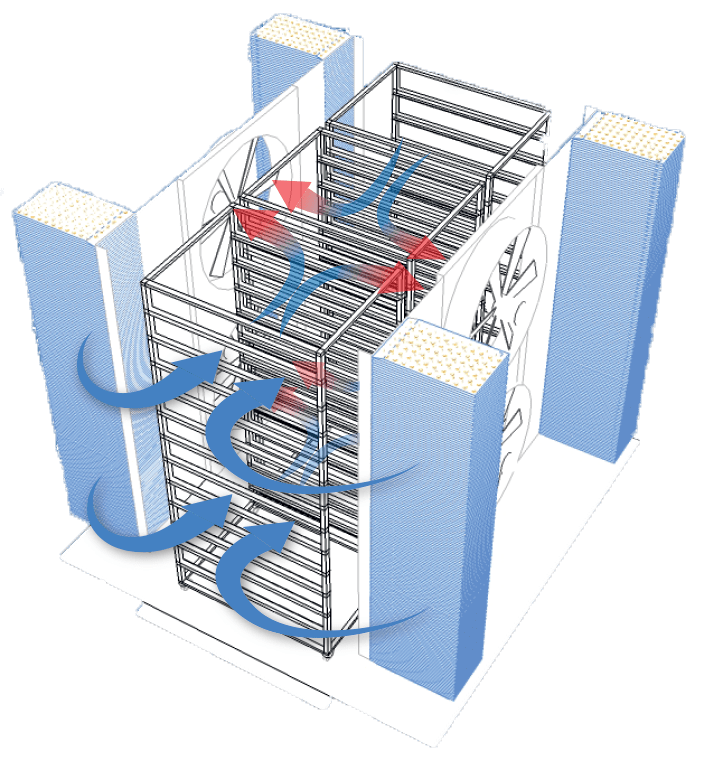

The use of perforated crates, pallets or particularly bulky trolleys is a barrier to the passage of air over the product. For these situations, ACFRI has developed a high-performance ventilation system.

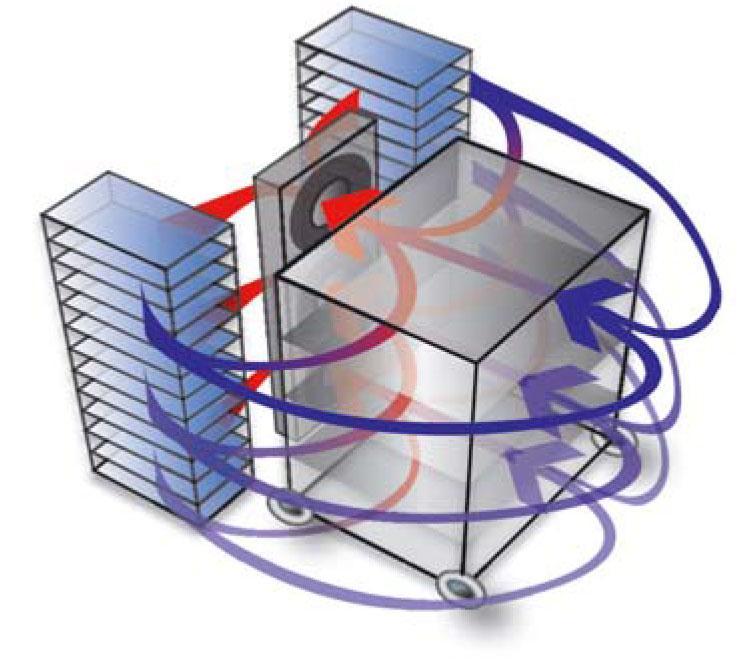

Ventilation is provided by a double air circuit on each side of the trolleys.

This device can be combined with the system for reversing the ventilation direction during the cycle.

- Product identification

- Temperature alarm

- Adjustable alarm threshold

- Input/output display

- Double temperature measurement

blow moulding, and product core

- Induction rechargeable

- Communication of temperatures in real time

- Multi-cell box

- WIFI settings

- ACFRI Soft interfacing

- Data recording and archiving on PC

- Automatic display of cycle times

- Printing and archiving curves on a graphical viewer

- Ethernet connection (RJ45) and remote access

- Cycle compliance history

- Multi-user software