ACFRI designs innovative cooling and deep-freezing cells to guarantee the highest level of food safety, product performance and quality. Our exclusive technologies meet the needs of the foodindustry, catering, small businesses and industrial sectors.

Take food from +65°C to +10°C in a very short space of time to prevent bacterial proliferation.

of ACFRI's blast chillers to ensure rapid, even freezing, in particular to reach a core temperature of -18°C.

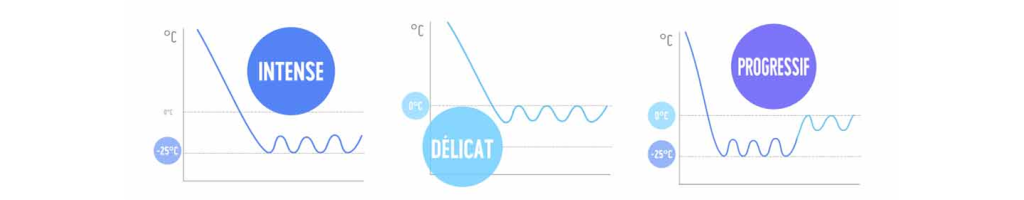

allows you to adjust the airflow in 3 modes: intense, delicate or gradual, depending on the sensitivity of the products.

using vertical tube evaporator technology, proof of ACFRI's long-standing expertise in this field.

Blast chilling involves lowering the temperature of products from +65°C to +10°C in a short space of time, thereby blocking bacterial proliferation and preserving the organoleptic qualities of the food.

Deep-freezing is a high-performance processing solution for preserving products naturally and without additives.

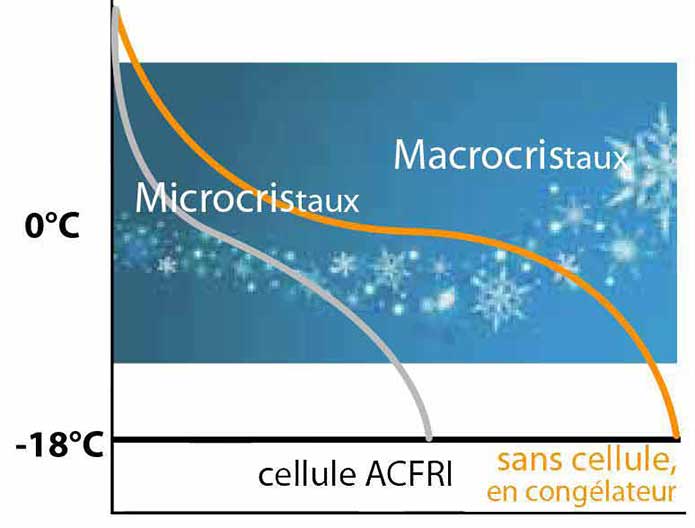

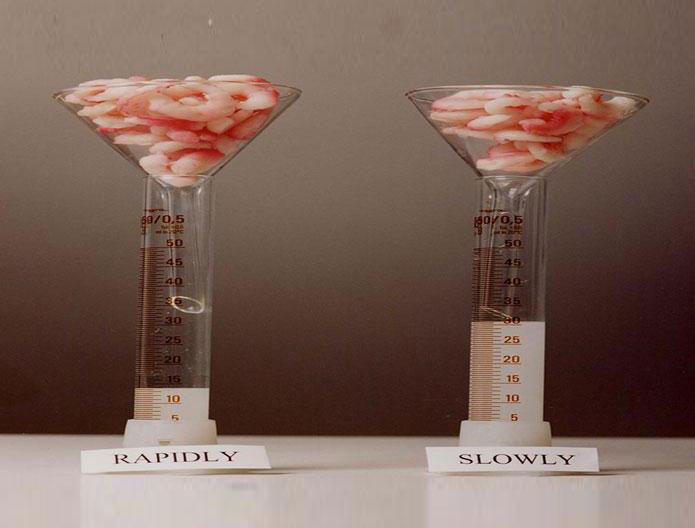

An ultra-rapid drop in temperature freezes the water inside the cells without bursting their envelope.

This is micro-crystallisation.

The organoleptic qualities of the product are thus perfectly preserved.

The difference between deep-freezing and simple freezing is perfectly spectacular when the product is defrosted.

Macro crystallisation" results from slow freezing (lack of air speed, insufficiently low temperature, lack of homogeneity) and leads to a significant release of the water contained in the product.

*After thawing, the frozen product (left) retains all its organoleptic qualities and releases virtually no water, unlike the slow-frozen product (right).

The exclusive ACFRI evaporation and ventilation system ensures perfectly uniform freezing throughout the blast freezer

ACFRI's blast freezers guarantee the quality of frozen products with ultra-low temperature performance and no gas consumption.

The exclusive ACFRI ventilation technology ensures that the ultra-low temperature is blown evenly over the entire height of the load. All the products are thus hardened (on the surface) or stiffened (at the core) to guarantee high-performance slicing with reduced material loss.

The patented SIMPLY 3 system enables sequenced blowing, guaranteeing the core-to-surface homogeneity essential for fine slicing at high speeds.

Thanks to ultra-fast hardening, even the most fragile or multi-layered products retain their original shape and appearance. The risk of distortion, sticking or marking is eliminated, ensuring an impeccable finish.

The solidity achieved by the material allows precise, regular cutting without waste. This control improves the productivity of production lines by increasing output while preserving product quality.

With the patented SIMPLY

3, the air is blown in intelligent sequences that alternate in intensity and direction. This dynamic airflow management means that the product is cooled progressively and evenly, without excessive hardening on the surface or soft spots in the core.

The exclusive ACFRI ventilation system blows at ultra-low temperature to prevent the ice cream from evaporating when it comes out of the turbine or freezer.

This preserves the ice cream's expansion, ensuring a smooth, creamy consistency.

Overrun is perfectly maintained, guaranteeing a light, supple and creamy ice cream. The texture is stabilised, with no loss of volume, for impeccable consistency and an optimal taste experience.

Hardening makes subsequent packaging and storage stages safer. It gives the product better hold, reduces the risk of crystallisation and ensures uniform quality throughout production, even at high output.

The flow of ultra-low temperature air is distributed evenly over the entire surface and through the mass of the product. This regularity prevents the formation of excessive thermal gradients.

The exclusive ACFRI ventilation system provides a blowing cycle at positive, sequenced and controlled temperatures for thawing all types of frozen products.

Defrosting in this way is guaranteed without any untimely cooking or edge effects. The speed of thawing also limits product oxidation caused by prolonged storage in a static refrigerator.

Every food regains its natural suppleness and original flavour. Juices stay inside, shapes are maintained, and even the most fragile products come out ready to use, as if they had never been frozen.

Thanks to a controlled temperature rise, defrosting is rapid but gentle. This limits oxidation and guarantees maximum food safety, while preparing the product for further processing without loss of yield.

Thanks to fine control of flow and temperature levels, each product receives exactly the amount of necessary heat. The core and the surface are changing from synchronised, guaranteeing defrosting and a uniform finish impeccable.